We used an automated demand response (ADR) protocol to secure cash incentives and energy savings for a building Owner. We integrated the ADR protocol into a building management system (BMS). The BMS would efficiently control over 128 Packaged Air Conditioning units for demand management and response protocols. Demand management generates cost savings while demand response generates cash revenue for this building.

Tenants in this building have been demanding the Owner to change the classic Manhattan industrial styled look of their showrooms to a homey and cozy one. The new look would be indicative of a suburban or coastal style residential setting. From a facilities standpoint, this required removal of ducted air conditioning systems and replaced with ductless split VRV air conditioning units manufactured by Daikin.

Daikin VRV Condensing Units

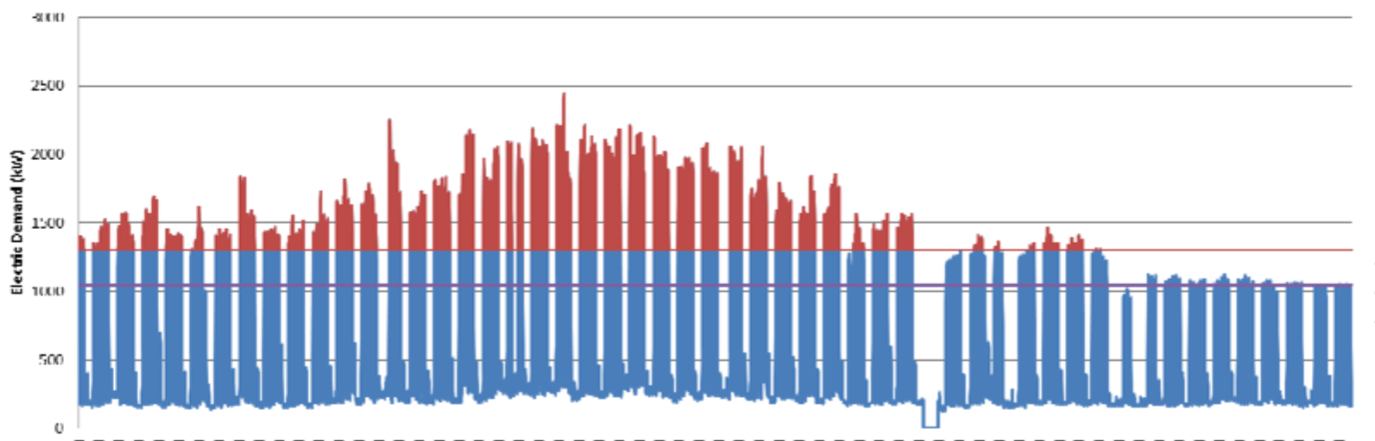

The result was over 128 mutually exclusive air conditioning systems that provided excellent temperature and humidity control. However the equipment operated sporadically which contributed to a volatile building kW demand profile and low load factor. Most noteworthy, these conditions further resulted in less than favorable electric supply prices and undue stress on building electrical systems.

Sporadic kW Demand from Distributed HVAC Systems

NYDC engaged LC Associates to evaluate potential alternatives to the existing condition. After modeling several options LCA concluded that the most cost effective means and methods available was to deploy a building wide energy management and automated demand response system. The ConEdison Demand Management Program (DMP) offered incentives to lower and “manage” kW demand of buildings.

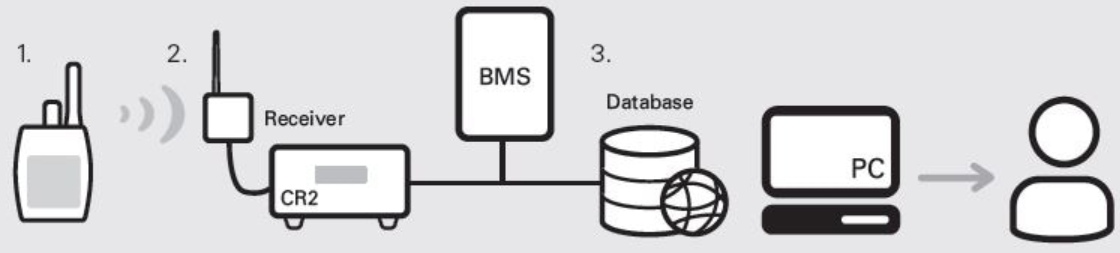

LC Associates led a team of ConEdison Market Partners i.e. the “Green Team”. The Green Team collaborated on the design of a building automation system that would permanently reduce kW demand, In addition, the system would also provide automated demand response for NYISO curtailment opportunities.

We installed controls on approximately 95 packaged air conditioning systems manufactured by Carrier and Skymark and 33 Daikin ductless packaged units. The Daikin’s proved quite a challenge because they were fully electronic. Daikin delivered a fully electronic state-of-the art system with a comprehensive BacNet interface. The entire system required a custom DMP algorithm which LC Associates designed and Delta Controls Contractor PEPCo implemented.

Building Automation System with constant feedback loop

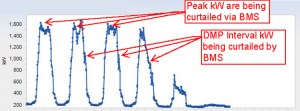

To constantly monitor space temperature, unit status and building kW demand, we developed a recursive ADR protocol. Becasuse information is constantly fed back into the algorithm for fine tuning, we had amazing results. We designed the protocol to pre-cool the building during summer days. Another feature we programmed, was to limit the total number of AC units operating at the same time to 80% . To prevent overheating, we programmed the system to override itself to prevent any space from exceeding 74 degF.

BMS System Limits Peak Demand of AC Unit Network

The system took about 90 days to complete. After a month of fine-tuning, we found that the BMS system limited coincident air conditioner operation to 60%. Most importantly, space temperatures of 72 degF were also maintained! The building is situated on a corner block. The building’s lobby entrance faces east and the west side of the building is in the shadows of its neighbor. Therefore only two sides of the building had substantial solar gain.

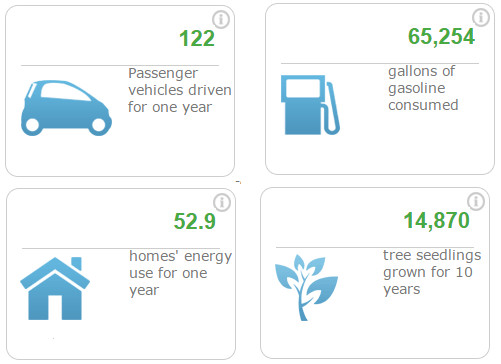

The carbon offset for this project is based upon saving 841,000 kWh annually. Most noteworthy, this energy savings results in 639 Tons of Carbon Dioxide removed from the atmosphere. As a result this CO2 avoidance roughly equates to the following metrics:

Carbon Offset Equivalence for this Project

We used a Delta Controls building automation system for this project. To control the Daikin equipment, we selected Delta Controls for its native BacNet architecture. Peconic Controls is a ConEdison Market Partner and has extensive experience deploying Delta Controls systems.

Participating ConEdison Market Partners

LC Associates. New York City’s premier Energy Services Company that for over 18 years has filed for over $100M in cash payments for its customers participating in the NYSERDA energy efficiency programs. You can check out our landing page to learn more by clicking here: ConEdDMP.Cutone.org

LC Associates. New York City’s premier Energy Services Company that for over 18 years has filed for over $100M in cash payments for its customers participating in the NYSERDA energy efficiency programs. You can check out our landing page to learn more by clicking here: ConEdDMP.Cutone.org

Peconic Controls. Delta Controls building automation distributor and ConEdison Market Partner specializes in HVAC automation.

Peconic Controls. Delta Controls building automation distributor and ConEdison Market Partner specializes in HVAC automation.