In this section, I’m going to describe the highlights of this program. Firstly, ConEdison is offering to pay up to 85% of project costs. Simply complete your project by 11/15/2020. Secondly, LC Associates will survey your building, prepare an application and secure your cash incentive. Building owners can then implement the project through their favorite contractor of have LC Associates provide a turnkey solution.

Your existing boilers have a long 40 year lifespan. However, as they age, their efficiency drops from around 70% down to 55%. In other words, if your boiler is at or near the end of its useful life, consider upgrading to an energy efficient >82% boiler. ConEdison may pay up to 85% of this project costs.

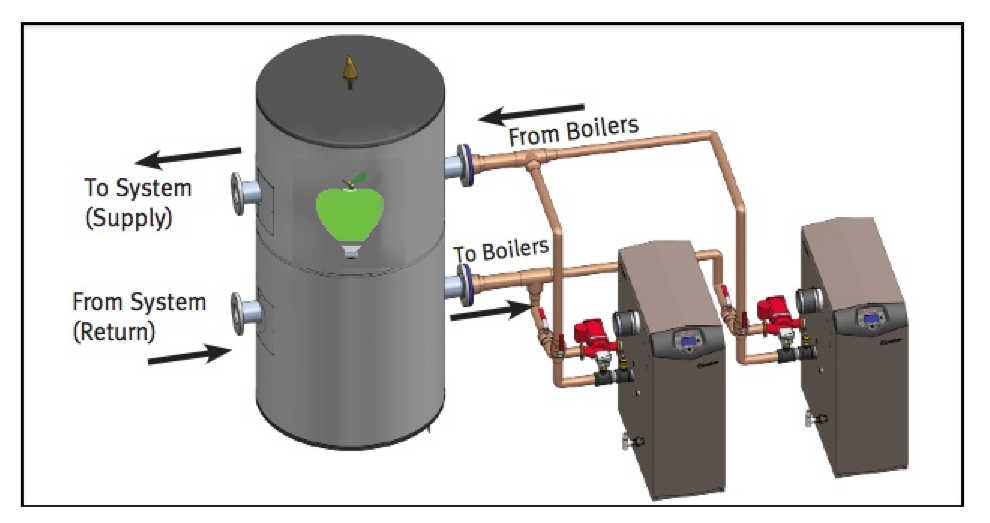

Condensing boilers generate hot water and can have efficiencies up to 97%! On the other hand, compare this to a common atmospheric hot water heater/boiler with a 75% energy efficiency rating. In addition, the case study below is a great example illustrating how we can secure funding for your project.

Not ready to replace your boiler? Consider an EnerGuard boiler control system. The EnerGuard will save you 15% in fuel costs and double as a building management system. The EnerGuard runs off the Delta Control platform and can be expanded for a building wide energy management and automation system.

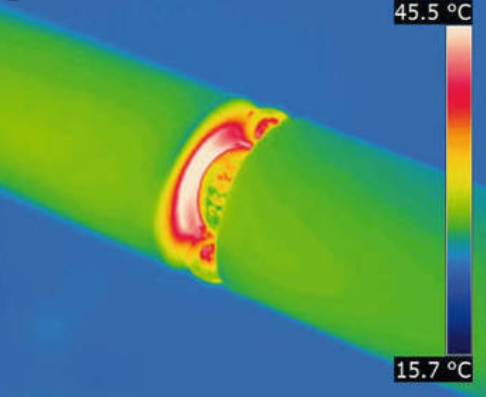

Insulating pipes and hot surfaces is the fastest natural gas cost recovery measure. The ConEdison incentive program may cover a significant portion of the implementation cost. LC Associates will survey your piping systems and provide a detailed analysis required by ConEdison to offer funding.

The existing plant was an array of eight cast iron boilers installed in 1983, about 33 years ago. Cast iron boilers can last 50 years or more if maintained. However traditional boilers were designed in a bygone era where natural gas was plentiful. During those days it seems like climate change may have been just a passing concept.

Natural Draft cast iron boilers typically have a 70% annual fuel utilization efficiency (AFUE) out of the box. However a 33 year old boiler can experience efficiency losses down to 50%. Consequently antiquated cast iron boilers may require twice the amount of natural gas for every unit of heating energy.

Condensing boilers when new have an AFUE of around 97%! The AFUE would deteriorate over time like a cast iron boiler. However this type of boiler already starts out 20 percentage points ahead!

The cost of this boiler upgrade came with a size-able price tag, approximately $330,000. What is amazing here is that the array of boilers was smaller in size to a mini-van. Without a cash incentive, this project would have a simple payback of 4.23 years. However building owners are hesitant to invest this much capital into a depreciating asset. Heating and related costs are generally passed through to Tenants. Landlords have less appetite to invest their capital into energy efficiency projects if the Tenants are funding the operating costs.

However taking that $330,000 price tag and reducing it down to $99,000 paints a different picture. Now the simple payback is only 1.27 years. Given commercial buildings are always “for sale”, Owners prefer to invest capital if the simple payback is around 1 year. The Owner now has a building with a higher Net Operating Income (NOI). Buildings with higher NOI’s have a higher valuation and can be sold for more margin.

Do you want to learn more? Feel free to schedule a free one-on-one appointment and speak with one of our engineers.

Amazingly, natural draft boilers have been around for thousands of years. However, they were not widely used for space heating until the industrial revolution.

Natural draft boilers in our project utilize natural gas for fuel. Because natural draft boilers rely on the hot combustion air to draft naturally, a common trait of natural draft boilers are that the burners are near the bottom of the system.

Natural draft boilers must “lift” the air from the bottom of the boiler up through the heat exchanger and through the flue. As a result, this heavy lifting takes energy away from the heating process and lowers the efficiency of the boiler.

In contrast, condensing boilers, are extremely energy efficient because they are able to provide ample heat while operating at lower temperatures.

In contrast, atmospheric boilers operating at lower temperatures results in condensation forming within the venting systems. Furthermore, condensation can be harmful to the heat exchangers of traditional boilers. To sum up, lower operating temperatures result in less energy consumption, less lift, and keep more heat in the heating system. As a result, good condensing boilers can attain energy efficiency of 90% or more.

LC Associates has been helping Clients reduce their energy costs, carbon footprint and energy consumption for almost 20 years. Above all, our Team consists of passionate engineers that are able to connect with our Customers and solve their problems in the most cost-effective and efficient manner. You can read about what we do by clicking this link. We are trusted advisers to some of the most Iconic Institutions of New York City, certainly we must be doing something right. Feel free to give us a call at 212.579.4236 to schedule a call or meeting with one of our engineers. Alternatively use the booking widget on this web page to schedule a call at a time convenient for you.