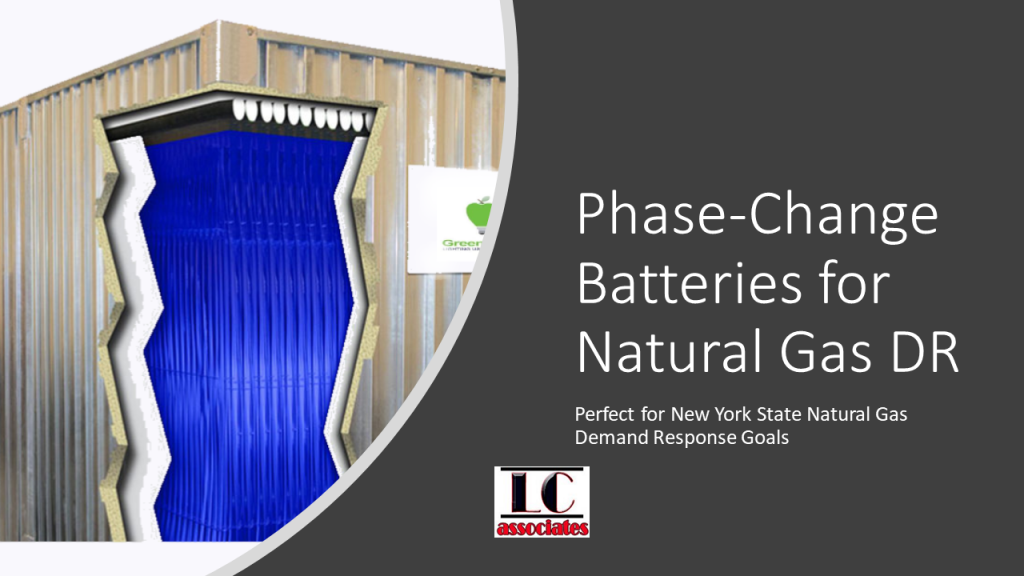

Most engineering professionals understand Thermal Energy Storage (TES) systems as it relates to electrical demand response. New York City is embarking on an aggressive program to reduce fossil fuel combustion in NYC. One of the methods of achieving this is to offer a natural gas demand response program.

Traditional TES systems use ice made during off-peak hours for daytime cooling applications. TES systems support the electric grid by moving electric day time loads over to the off-peak hours. Utilities and agencies such as ConEdison and NYSERDA have offered to subsidize these projects through cash incentives. These cash incentives of course help offset the initial cost of these these systems.

TES systems offer natural gas demand response capabilities if a building uses natural gas fired, or driven, chillers for cooling. HOWEVER, given the large and dense population of natural gas boilers in New York City, a TES system is a great solution for Natural Gas DR programs. The obstacle however is that traditional TES system use ice to store thermal energy for cooling.

A new and alternative type of TES system using tried and true phase change materials (PCM) are making its way into the market place. The manufacturer of a PCM battery can design it to freeze at very high temperatures. For example, using a boiler at night to generate 200 degF hot water can be stored in a semi-solid PCM Battery. A Building can use the PCM Battery to discharge hot water during the day and shut down the boiler. How do you freeze solids at 180 degF?….read on below.

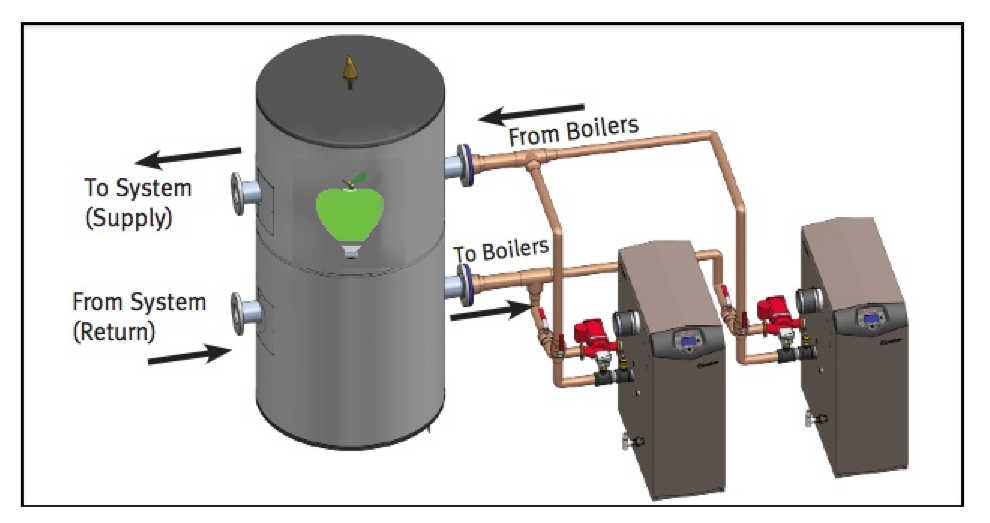

PCM Thermal Storage batteries work just like a hot water storage tank. The difference is that it does not leak and has lower losses than traditional hot water storage tanks.

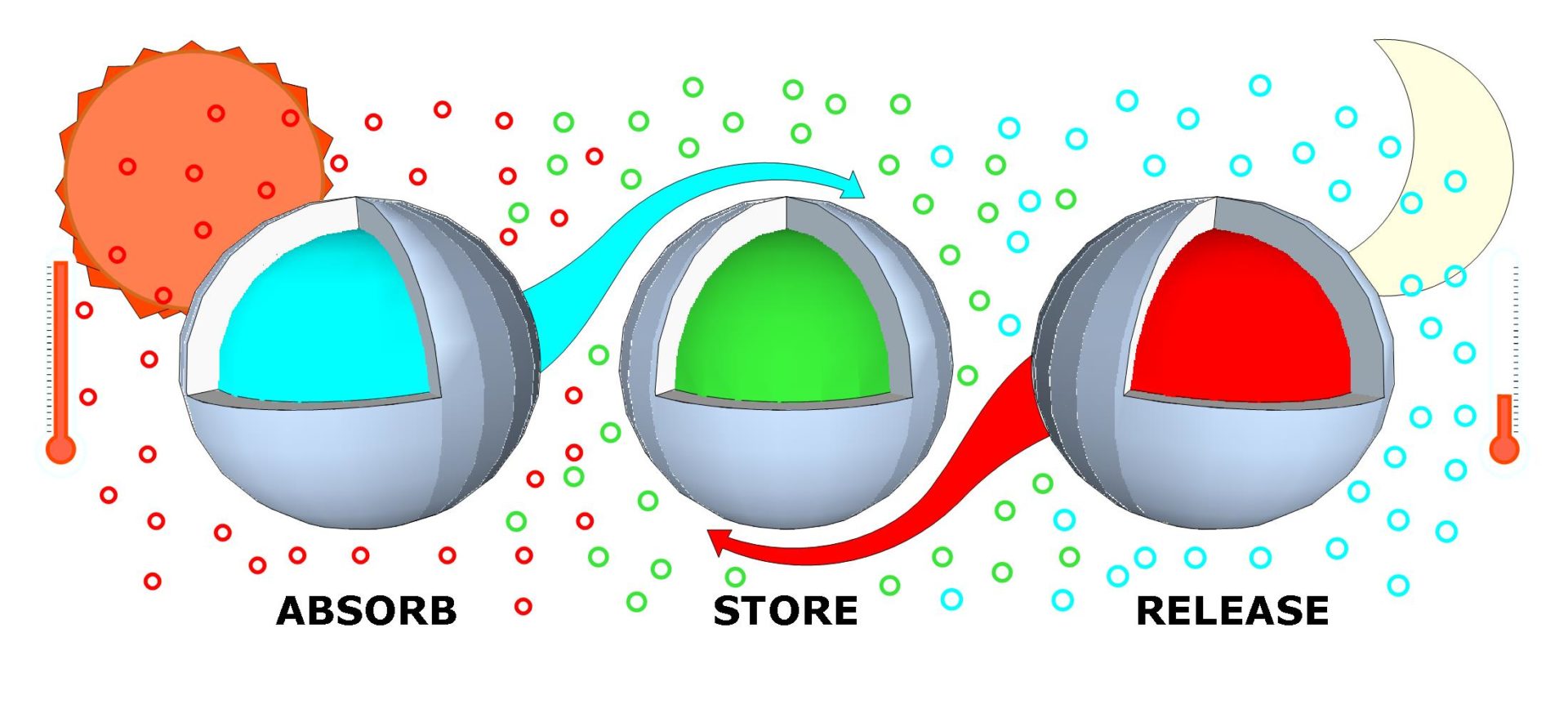

A phase change material absorbs and releases thermal energy in order to maintain a regulated temperature. When a PCM is in its’ solid phase it will absorb heat. As the external temperature rises the PCM will turn into a gel/liquid. As the temperature drops, the cycle is reversed. It is the PCM’s ability to store and release large amounts of heat that has made it a subject of interest in the energy efficiency and management fields.

A quick search on Wikipedia will show that industry has used PCM’s since the late 19th century as a medium for thermal storage applications. PCM’s have been used in such diverse applications as refrigerated transportation, for rail, and road applications, and their physical properties are therefore, well known.

Unlike the traditional ice storage systems that freeze and thaw around 32degF, manufacturers can program the PCM systems to freeze and thaw at 42 degF or 180 degF. For example, Buildings can use PCM batteries with any conventional water chiller for cooling or a natural gas boiler for heating.

Some of the benefits of using a PCM TES system include: