Original elevator switch gear next to modern electronic elevator controls.

Wow! – This one belongs at the Met!

Elevators manufactured more than 20 years ago are significantly less energy efficient than today’s newer models. The energy efficiency of elevators has greatly improved with technological advances in motor controls and other technologies. According to the American Council for an Energy Efficiency Economy (ACEEE) current technology is able to cut up to 75% of elevators energy use.

Many utility companies, such as ConEdison provide rebates for equipment and process improvements that generate energy savings. Additional bonus incentives for elevator controls that implement automated demand response .

Additionally the New York Independent System Operation (NYISO) offers incentives to buildings for participating in the Demand Response Program. Modern elevator controls allow owners to reduce elevators energy use during curtailment events.

Motor/Generator (MG) Sets are legacy pieces of equipment. MG Sets turn AC power into DC power using a relatively ancient, but reliable analog technology.

MG sets consist of an AC induction motor that consumes electricity and turns a DC Generator. The DC generator then delivers DC power to a DC elevator motor. The MG Set is a “spinning reserve” DC power source. A spinning reserve power source is always running, or spinning, and always on stand. A spinning reserve power supply consumes energy even if it is not needed. Some MG Sets come with delay timers that would turn off the MG sets during long periods of elevator idle time. These timers consist of relays that would wear out and eventually be bypassed by the building engineers. MG Sets without controls would be in a perpetual spinning reserve state, consuming energy when not needed.

MG Sets when unloaded can be as much as 30% efficient as the only work being done is rotating a motor shaft. When the MG set is fully loaded it is about 70% efficient.

Call to see how we can get $5,000 to $20,000 or more per elevator car!

The simplest energy conservation measure when an MG Set is involved is to replace it with an electronic SCR Drive. These drives convert AC power to DC power at an efficiency of 97%. We have secured cash incentives for over 400 elevator modernization projects.

Re-Generative drives came into the market and use a novel approach to elevator energy savings.

Elevator Brake Resistors

Elevator Braking Circuit

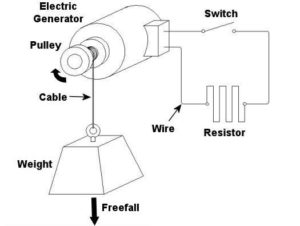

Ever wondered how elevators stop? When an elevator is required to stop, the control system closes a switch. This switch places a bank of resistors in parallel to the elevator motor. The resistors have a lower resistance than the motor and rob the motor of energy which slows it down. The resistors convert the electricity to heat and dissipate it into the elevator room. Sounds like a waste of energy right?

This heat winds up filling up the elevator room. Some buildings have to install air conditioning systems to move the excess heat out of the building.

Instead of traditional braking resistors, elevator manufacturers can install a re-generative circuit. A re-gen circuit may consist of capacitors and inductive circuits like transformers, or solid state devices. Rather than dissipating this energy as heat, re-gen circuits will transfer this electric energy into the local electric grid. This technology has been shown to save over 35% of elevator energy consumption.

I remember my first re-gen project. At the time, NYSERDA was offering cash incentives for elevator modernization projects. We were hired by the Sapir Organization to expedite some cash incentives over at 100 Church Street. 100 Church Street is now owned by SL Green. We installed data loggers on the new equipment, and measured the energy savings to be around 40%. Our original projection was a 12-15% energy savings. After reviewing the data with NYSERDA’s technical consultant, we thought the data logger malfunctioned, or that the technician did not connect it properly.

We all came to the conclusion that the data logger was damaged or not connected properly, because the data values were negative in some cases. NYSERDA’s technical consultant then installed their own meter. We purchased an expensive hand-held Fluke kW meter to take spot measurements as well. Surprisingly, the interval data had the same negative values in their profile! It turns out that the kW data loggers were bi-directional and measuring nega-watts. The re-gen drive was feeding electric power back into the building’s electric grid for use by the building!

Here is a cool video from a manufacturer that demonstrates how resistive and regenerative braking works.

If your building wants to get deep energy savings, try opting for the elevator AC Motor and Regen Drive conversion. DC to AC elevator modernization projects have generated 70% energy savings in some cases.

Energy savings comes from removing the MG Set and converting reliable, but energy inefficient DC Elevator motors into AC Motors. AC motors can have efficiencies of over 91% and only a 3% parasitic load when idling. AC Motors can have a 30% or more efficiency improvement over DC Motors. Coupling a DC to AC Motor conversion with a re-gen drive now gets you 65-75% energy savings!

AC motors do not have brushes like DC Motors do. DC Motors have carbon brushes that wear away and spew black dust all over your elevator mechanical room. DC Brushes wear away and elevator maintenance personnel need to replace them constantly. Elevator systems without DC Motor Brushes have lower maintenance costs.

Effects of Elevator DC Motor Dust. These switches used to be shiny and new once.

Elevator systems are by far, in my opinion, one of the greatest engineering marvels. American workers have built legacy elevator controls mostly by hand during the era of Thomas Edison. Buildings still use these legacy elevator systems today. Steam Punk fans the world over would love to have these great pieces of American Engineering on display.

This is not the Smithsonian – this is a functioning elevator control system.

However owning such a great piece of American History comes with responsibility. If the parts break, you may need to hire a blacksmith to replace them.

A good friend of mine, John Harvey, is an excellent blacksmith, in case anyone needs him to make parts.

https://www.facebook.com/johndharvey/videos/10157217124057323/

LCA will install instrumentation systems on your vertical transports systems. Our engineers will conduct a deep dive analysis to maximize your potential cash incentive payment. LCA will prepare all applications and manage your incentive program from start to finish. Our company has secured hundreds of thousands of dollars for elevator modernization projects since 2002!